Introduzione alla ceramica di precisione

Importanza e applicazioni

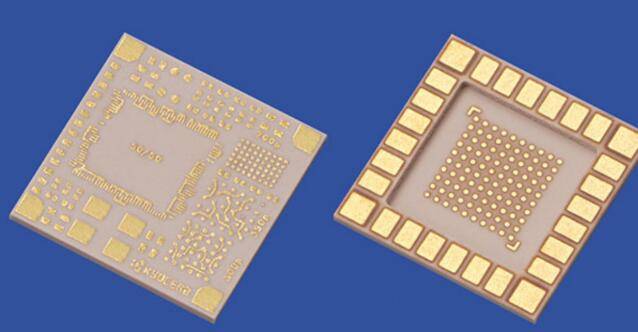

I componenti ceramici di precisione svolgono un ruolo fondamentale in diverse tecnologie all'avanguardia grazie alle loro eccezionali proprietà meccaniche e alla loro resistenza in condizioni estreme. Nel regno della produzione di circuiti integrati questi componenti sono indispensabili per mantenere l'elevata precisione e affidabilità richiesta dai dispositivi a semiconduttore. La loro elevata resistenza e durezza garantisce che possano resistere alle rigorose esigenze del processo di produzione senza compromettere le prestazioni.

In tecnologia laser , le ceramiche di precisione sono utilizzate per la loro capacità di mantenere l'integrità strutturale sotto l'irradiazione laser ad alta energia. La loro resistenza agli shock termici e la chiarezza ottica li rendono ideali per le applicazioni in cui la manipolazione precisa del fascio laser è fondamentale, come nel caso dei laser medicali e degli strumenti di taglio industriali.

Il campi di rilevamento beneficiano in modo significativo dell'elevata sensibilità e stabilità delle ceramiche di precisione. Questi componenti sono spesso utilizzati in sensori che richiedono una raccolta dati accurata e affidabile, come quelli presenti nei sistemi di monitoraggio ambientale e nell'automazione industriale. La loro durata garantisce prestazioni a lungo termine, anche in ambienti difficili.

La tecnologia superconduttiva sfrutta le proprietà uniche delle ceramiche di precisione per ottenere la superconduttività ad alta temperatura. Questi materiali sono essenziali per lo sviluppo di magneti superconduttori e altri componenti che richiedono una bassa resistenza elettrica e un'elevata densità di corrente. La loro capacità di operare a temperature più elevate rispetto ai superconduttori convenzionali apre nuove possibilità per le tecnologie ad alta efficienza energetica.

In applicazioni biomediche Le ceramiche di precisione sono apprezzate per la loro biocompatibilità e resistenza meccanica. Vengono utilizzati in impianti e protesi che devono integrarsi perfettamente con il corpo umano. La loro resistenza alla corrosione e all'usura garantisce che questi dispositivi medici rimangano efficaci per lunghi periodi, migliorando i risultati dei pazienti e riducendo la necessità di frequenti sostituzioni.

Nel complesso, la versatilità e la robustezza dei componenti ceramici di precisione li rendono indispensabili in diversi settori tecnologici, favorendo l'innovazione e migliorando le prestazioni dei sistemi critici.

Sfide e limiti

Le ceramiche di precisione, pur offrendo numerosi vantaggi come l'alta resistenza e la resistenza ad ambienti estremi, presentano sfide significative che ne complicano la produzione e l'utilizzo. Uno dei problemi principali è la loro elevata durezza e fragilità intrinseca, che li rende notoriamente difficili da lavorare. Questa caratteristica non solo aumenta la complessità del processo di produzione, ma rende i materiali più inclini a crepe e fratture sotto stress meccanico.

La fragilità delle ceramiche di precisione richiede l'uso di tecniche di lavorazione specializzate, che spesso comportano costi operativi più elevati. Ad esempio, i metodi di taglio tradizionali sono meno efficaci a causa della resistenza del materiale alla deformazione, con conseguente aumento dell'usura degli utensili da taglio e del consumo energetico. Inoltre, il rischio di formazione di microcricche durante la lavorazione può degradare la qualità complessiva e le prestazioni del prodotto finale, aumentando ulteriormente i costi di produzione.

Inoltre, l'elevata durezza di queste ceramiche può limitarne l'applicabilità in alcuni scenari in cui sono richieste flessibilità e facilità di modellazione. Questa rigidità può anche rappresentare una sfida nell'integrazione di componenti ceramici di precisione in sistemi che richiedono adattabilità e resistenza a condizioni dinamiche.

In sintesi, se da un lato le ceramiche di precisione sono altamente desiderabili per le loro caratteristiche prestazionali, dall'altro la loro elevata durezza e fragilità introducono notevoli ostacoli alla produzione, tra cui un aumento dei costi e il potenziale di difetti del prodotto. Per affrontare queste sfide sono necessarie tecnologie di lavorazione innovative e un'attenta selezione dei materiali per ottimizzare l'equilibrio tra prestazioni e producibilità.

Tecnologie di preparazione per la ceramica di precisione

Stampaggio a iniezione

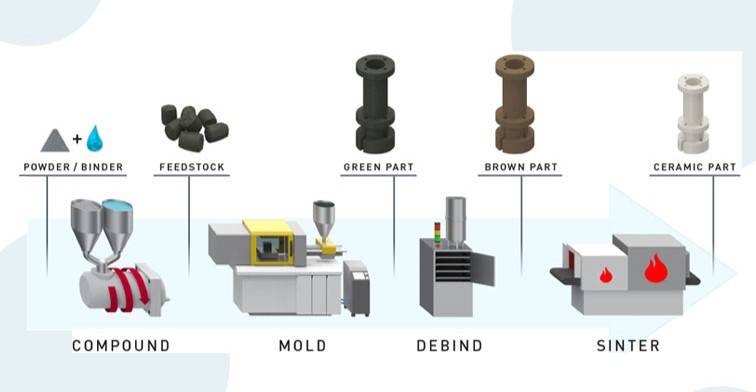

Lo stampaggio a iniezione di ceramica (CIM) è un processo sofisticato che fonde le tradizionali tecniche di iniezione di polimeri con metodi avanzati di preparazione della ceramica. Questo approccio innovativo consente di creare componenti ceramici intricati e su piccola scala con un'eccezionale precisione dimensionale e una densità uniforme. Il processo inizia con la miscelazione di polveri ceramiche fini con un legante polimerico, che viene poi iniettato in uno stampo ad alta pressione. Una volta formato il pezzo, il legante viene rimosso attraverso un processo di debinding, seguito dalla sinterizzazione per ottenere la struttura ceramica finale.

Uno dei vantaggi principali del CIM è la capacità di produrre geometrie complesse che sarebbero difficili o impossibili da ottenere con i metodi convenzionali di formatura della ceramica. Questa capacità è particolarmente preziosa in settori come l'aerospaziale, i dispositivi medici e l'elettronica, dove la richiesta di componenti ad alte prestazioni e di precisione è fondamentale. L'uniformità della densità ottenuta con il CIM garantisce proprietà meccaniche costanti sull'intero pezzo, un aspetto cruciale per le applicazioni che richiedono affidabilità e durata.

Inoltre, il CIM offre significativi risparmi sui costi e miglioramenti dell'efficienza rispetto ai metodi tradizionali di produzione della ceramica. Consentendo la produzione di componenti di forma quasi netta, il CIM riduce la necessità di un'ampia post-lavorazione, riducendo così gli sprechi di materiale e i tempi di produzione. Questa efficienza è ulteriormente migliorata dalla possibilità di automatizzare il processo di stampaggio a iniezione, con conseguente qualità costante e riduzione dei costi di manodopera.

In sintesi, lo stampaggio a iniezione di ceramica rappresenta una tecnologia all'avanguardia che colma il divario tra la lavorazione dei polimeri e l'ingegneria ceramica, offrendo una soluzione versatile per la produzione di componenti ceramici di alta precisione con notevoli caratteristiche prestazionali.

Stampaggio a iniezione di gel

L'Injection Gel Forming rappresenta un significativo progresso nella produzione di ceramica, integrando perfettamente le tradizionali tecniche di stampaggio della ceramica con sofisticati metodi di polimerizzazione organica. Questo processo innovativo è particolarmente vantaggioso per la produzione di grezzi ceramici di dimensioni quasi nette e ad alta resistenza, essenziali per la fabbricazione di componenti ceramici grandi e complessi. A differenza dei metodi convenzionali, che spesso richiedono una lunga post-lavorazione per ottenere le forme e le resistenze desiderate, l'Injection Gel Forming riduce significativamente il tempo del ciclo di stampaggio, migliorando così l'efficienza produttiva.

Il processo sfrutta i punti di forza dei materiali ceramici e polimerici, consentendo la creazione di geometrie complesse che in precedenza erano difficili da ottenere con i metodi tradizionali. Combinando queste tecnologie, i produttori possono produrre componenti in ceramica con densità uniforme e proprietà meccaniche superiori, che li rendono ideali per le applicazioni che richiedono alta precisione e durata. Questo metodo non solo snellisce il processo di produzione, ma riduce anche al minimo gli scarti di materiale, contribuendo a un ambiente di produzione più sostenibile.

In sintesi, l'Injection Gel Forming è una tecnica all'avanguardia che affronta i limiti dello stampaggio ceramico tradizionale, offrendo una soluzione versatile per la produzione di componenti ceramici ad alte prestazioni con forme complesse e cicli di stampaggio brevi.

Stampaggio 3D

La stampa 3D rivoluziona la produzione di ceramiche di precisione, consentendo la creazione di parti altamente complesse con velocità ed efficienza senza precedenti. A differenza dei metodi di stampaggio tradizionali, la stampa 3D integra processi avanzati di progettazione assistita da computer (CAD) e di produzione, consentendo la deposizione strato per strato dei materiali senza la necessità di stampi. Questo metodo è particolarmente vantaggioso per la produzione di componenti ceramici intricati che sarebbe difficile o impossibile creare con le tecniche tradizionali.

La flessibilità della stampa 3D si estende a un'ampia gamma di materiali ceramici, ciascuno con proprietà uniche che possono essere sfruttate per applicazioni specifiche. Ad esempio, la zirconia, l'allumina e il nitruro di silicio sono comunemente utilizzati nella stampa 3D grazie alla loro elevata forza e resistenza a condizioni estreme. La capacità di stampare questi materiali in geometrie complesse garantisce che i prodotti finali soddisfino requisiti dimensionali e standard prestazionali precisi.

Inoltre, la stampa 3D riduce significativamente il tempo necessario per la produzione, in quanto elimina la necessità di molteplici configurazioni di utensili e di fasi intermedie. Questo processo semplificato non solo accelera la produzione, ma riduce anche al minimo gli scarti, rendendolo un'opzione ecologica. La tabella seguente evidenzia i principali vantaggi della stampa 3D nella produzione di ceramica:

| Vantaggi | Descrizione |

|---|---|

| Elevata complessità | Capacità di creare geometrie intricate, difficili da ottenere con gli stampi. |

| Riduzione dei tempi di produzione | Elimina la necessità di molteplici configurazioni di utensili e di fasi intermedie. |

| Flessibilità dei materiali | Supporta una varietà di materiali ceramici con proprietà uniche. |

| Scarti ridotti al minimo | Il processo semplificato riduce gli sprechi di materiale e aumenta l'efficienza. |

In sintesi, la stampa 3D si distingue come tecnologia trasformativa nel campo della ceramica di precisione, offrendo capacità senza precedenti in termini di complessità, velocità e versatilità dei materiali. La sua integrazione nel processo di produzione apre la strada a soluzioni innovative e a prestazioni migliori in vari settori.

Tecnologie di lavorazione per la ceramica di precisione

Lucidatura chimico-meccanica (CMP)

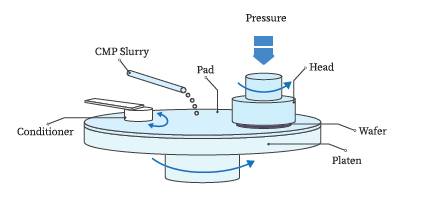

La lucidatura chimico-meccanica (CMP) è un processo critico nell'industria dei semiconduttori, utilizzato principalmente per ottenere la planarizzazione globale. Questa tecnica prevede l'uso di particelle abrasive in scala nanometrica che, in condizioni di alta temperatura e pressione, creano una nuova sostanza più morbida. Questa sostanza più morbida facilita la rimozione e consente di ottenere superfici ultra-lisce, essenziali per la fabbricazione precisa dei dispositivi a semiconduttore.

Il processo di CMP è molto sofisticato e comporta una complessa interazione di forze chimiche e meccaniche. Le particelle abrasive, spesso composte da materiali come silice o allumina, sono sospese in un impasto che contiene anche agenti chimici. Questi agenti reagiscono con la superficie del materiale da lucidare, creando uno strato sottile più suscettibile all'abrasione meccanica. La combinazione di reazioni chimiche e di abrasione meccanica garantisce una rimozione uniforme del materiale, che porta a una superficie piatta.

Uno dei vantaggi principali della CMP è la capacità di ottenere una planarizzazione globale, fondamentale per la fabbricazione di dispositivi semiconduttori multistrato. Senza la planarizzazione, le irregolarità della superficie potrebbero portare a difetti negli strati successivi, incidendo sulle prestazioni complessive e sull'affidabilità del dispositivo. La capacità della CMP di produrre superfici ultra-lisce riduce anche la probabilità di difetti, migliorando così la resa e la qualità dei componenti a semiconduttore.

Oltre che nella produzione di semiconduttori, la CMP ha trovato applicazione anche nella produzione di componenti ceramici di precisione. La tecnica è particolarmente utile per i materiali duri e fragili, in quanto consente la rimozione precisa del materiale senza causare danni significativi alla struttura sottostante. Ciò rende la CMP uno strumento prezioso per la fabbricazione di componenti ceramici ad alte prestazioni utilizzati in vari settori, tra cui quello aerospaziale, automobilistico e dei dispositivi medici.

Il processo di CMP, tuttavia, non è privo di sfide. Le alte temperature e le pressioni richieste possono portare all'usura delle apparecchiature, aumentando i costi di manutenzione. Inoltre, la scelta delle particelle abrasive e degli agenti chimici presenti nello slurry deve essere attentamente ottimizzata per garantire una lucidatura efficace senza causare danni eccessivi al materiale. Nonostante queste sfide, i vantaggi della CMP nell'ottenere superfici di alta qualità e ultra-lisce la rendono una tecnologia indispensabile nel campo della ceramica di precisione.

Lucidatura magnetoreologica

La lucidatura magnetoreologica (MRP) si distingue come metodo all'avanguardia nel campo della ceramica di precisione, offrendo precisione ed efficienza senza pari. A differenza delle tecniche di lucidatura tradizionali, la MRP sfrutta i fluidi magnetoreologici, materiali intelligenti che modificano le loro proprietà reologiche sotto l'influenza di un campo magnetico. Questa caratteristica unica consente di regolare in tempo reale il processo di lucidatura, garantendo un'elevata precisione e coerenza.

Uno dei vantaggi più significativi dell'MRP è l'assenza di usura degli utensili. I metodi di lucidatura tradizionali spesso soffrono di degrado degli utensili, che può portare a incongruenze nella finitura superficiale e richiedere frequenti sostituzioni degli utensili. Al contrario, l'uso di fluidi magnetoreologici elimina questo problema, mantenendo così un tasso di rimozione stabile e una qualità superficiale costante durante tutto il processo.

Tuttavia, l'applicazione della MRP non è priva di sfide. Il processo richiede una preparazione meticolosa e attrezzature sofisticate, che inevitabilmente fanno lievitare i costi. La complessità della configurazione e del funzionamento dei sistemi MRP, insieme agli alti costi associati ai materiali e ai macchinari specializzati, ne limita l'adozione diffusa in ambito industriale. Nonostante il suo potenziale per rivoluzionare la lucidatura di precisione, l'elevata barriera all'ingresso ne limita la scala industriale, rendendola più adatta ad applicazioni di nicchia e di alta precisione piuttosto che alla produzione su larga scala.

In sintesi, sebbene la MRP offra una notevole precisione, efficienza e longevità degli utensili, la sua applicazione industriale è limitata dai costi elevati e dalla complessa preparazione richiesta. I futuri progressi nella tecnologia e nell'ottimizzazione dei processi sono essenziali per rendere l'MRP più accessibile e conveniente, ampliando così la sua applicabilità nell'industria della ceramica di precisione.

Rettifica ELID

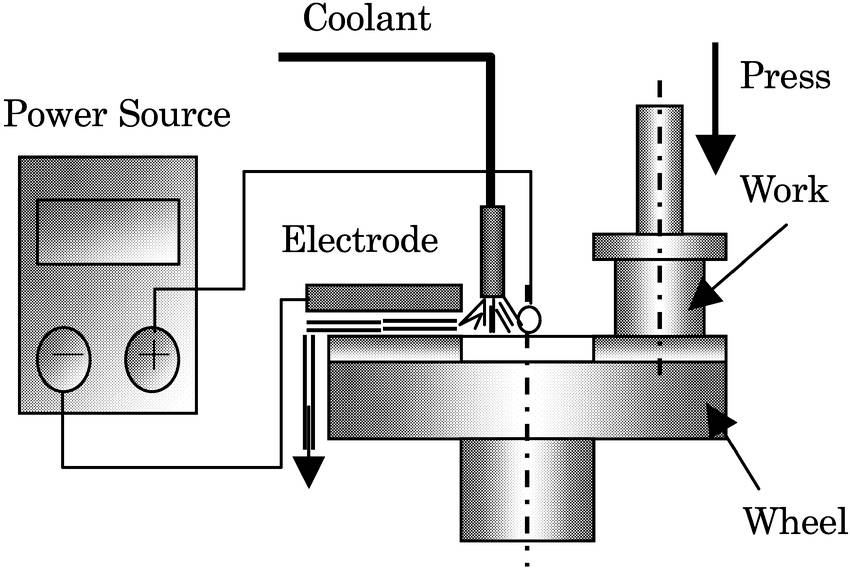

La rettifica ELID (Electrolytic In-process Dressing) è un'innovativa tecnologia di lavorazione degli specchi compositi che integra le tradizionali tecniche di scheggiatura, rettifica e lucidatura. Questo metodo impiega una soluzione acquosa contenente un elettrolita debole, che svolge un ruolo cruciale nella lavorazione di precisione dei materiali ceramici. Nonostante le sfide associate alla sua implementazione, la rettifica ELID promette molto bene per il futuro della lavorazione di precisione della ceramica.

Caratteristiche e vantaggi principali

-

Lavorazione integrata: La rettifica ELID combina diversi processi di lavorazione tradizionali, tra cui scheggiatura, rettifica e lucidatura, in un unico metodo coesivo. Questa integrazione snellisce il processo di produzione, riducendo la necessità di fasi separate e abbassando potenzialmente i costi di produzione.

-

Soluzione elettrolitica: L'uso di una soluzione acquosa con un elettrolita debole è una caratteristica distintiva della rettifica ELID. Questa soluzione facilita la rimozione precisa del materiale, migliorando la precisione e la levigatezza del prodotto finale. Il processo elettrolitico contribuisce inoltre a mantenere l'affilatura dell'utensile di rettifica, essenziale per ottenere risultati di alta qualità.

-

Idoneità per la ceramica di precisione: Data l'elevata durezza e fragilità delle ceramiche di precisione, i metodi di lavorazione tradizionali spesso faticano a garantire la precisione e la qualità superficiale richieste. La rettifica ELID, grazie alla sua capacità di gestire queste sfide, è particolarmente adatta alla lavorazione di componenti ceramici di precisione.

Sfide e considerazioni

Sebbene la rettifica ELID offra numerosi vantaggi, non è priva di sfide. La complessità del processo elettrolitico e la necessità di un controllo preciso della soluzione elettrolitica possono rendere difficile l'implementazione su larga scala. Inoltre, gli elevati costi iniziali di installazione e la necessità di attrezzature specializzate possono costituire un ostacolo all'adozione su larga scala.

Nonostante queste sfide, la rettifica ELID rimane una tecnologia promettente per il futuro della ceramica di precisione. La sua capacità di fornire risultati di alta qualità con un processo semplificato la rende uno strumento prezioso nella continua ricerca di metodi di lavorazione della ceramica più efficienti ed efficaci.

In sintesi, la rettifica ELID rappresenta un progresso significativo nel campo della lavorazione della ceramica di precisione, offrendo una combinazione di tecniche tradizionali e innovative per affrontare le sfide uniche poste da questi materiali.

Lavorazione laser

La lavorazione laser si distingue come metodo senza contatto e senza utensili, che offre una precisione senza pari, particolarmente vantaggiosa per i materiali ceramici fragili e duri. Questa tecnologia sfrutta la potenza dei fasci laser focalizzati per manipolare i materiali su scala micro e nano, rendendola ideale per attività complesse che i metodi di lavorazione tradizionali non riescono a gestire.

Tuttavia, sebbene la lavorazione laser eccella per precisione, non è priva di sfide. Garantire una precisione costante e mantenere un'elevata qualità della superficie può essere impegnativo. La natura della lavorazione laser richiede un controllo meticoloso di parametri quali la potenza del laser, la durata dell'impulso e la messa a fuoco del fascio, ognuno dei quali può avere un impatto significativo sulla qualità del prodotto finale. Inoltre, la natura senza contatto del processo rende complesso il monitoraggio e la correzione di eventuali deviazioni in tempo reale.

Nonostante queste sfide, la lavorazione laser rimane una pietra miliare nella produzione di ceramiche di precisione. La sua capacità di ottenere geometrie intricate e un'elevata precisione dimensionale la rende indispensabile per le applicazioni in cui i metodi tradizionali non sono all'altezza. Con l'avanzare della ricerca e della tecnologia, si prevede che la precisione e il controllo della qualità superficiale della lavorazione laser miglioreranno, consolidando ulteriormente il suo ruolo nel futuro della produzione ceramica di precisione.

Lucidatura al plasma

La lucidatura assistita da plasma rappresenta un nuovo approccio alla finitura delle superfici ceramiche, che sfrutta le proprietà uniche del plasma per ottenere una precisa rimozione del materiale. A differenza dei tradizionali metodi di lucidatura a umido, questa tecnica opera in un ambiente asciutto, attenuando i problemi legati alla gestione e allo smaltimento dei fluidi. L'irradiazione al plasma, caratterizzata da un'elevata energia e da specie reattive, consente l'incisione selettiva delle superfici dei materiali, facilitando così il raggiungimento di finiture ultra-lisce.

Tuttavia, l'adozione della lucidatura assistita da plasma non è priva di ostacoli. Una delle sfide principali è rappresentata dai tassi di rimozione del materiale relativamente più bassi rispetto alle tecniche convenzionali. Questa limitazione richiede tempi di lavorazione più lunghi, il che può rappresentare uno svantaggio significativo negli ambienti di produzione ad alta produttività. Inoltre, le attrezzature specializzate necessarie per la lucidatura assistita da plasma sono spesso proibitive, il che rappresenta un ostacolo finanziario all'implementazione industriale diffusa. Nonostante queste sfide, le ricerche in corso mirano a ottimizzare i parametri del plasma e a migliorare l'efficienza del processo, liberando potenzialmente il suo pieno potenziale nel regno della ceramica di precisione.

Processi di lucidatura dei compositi

I processi di lucidatura compositi rappresentano un progresso significativo nel campo della ceramica di precisione, offrendo un approccio sinergico per migliorare sia la qualità della superficie che l'efficienza della lavorazione. Questi processi combinano varie tecniche, tra cui la rettifica con vibrazione a ultrasuoni e la lucidatura chimico-meccanica (CMP), per ottenere risultati superiori.

La rettifica assistita da vibrazioni a ultrasuoni introduce vibrazioni ad alta frequenza nel processo di rettifica, che possono ridurre significativamente l'usura degli utensili e migliorare i tassi di rimozione del materiale. Questo metodo è particolarmente efficace per i materiali duri e fragili come le ceramiche di precisione, dove i metodi di rettifica tradizionali possono essere inefficienti e soggetti a difetti superficiali.

D'altra parte, la lucidatura chimico-meccanica (CMP) è una tecnica consolidata nell'industria dei semiconduttori, nota per la sua capacità di produrre superfici ultra-lisce attraverso l'interazione di particelle abrasive su scala nanometrica e reazioni chimiche. Se integrata con la rettifica a ultrasuoni, la CMP può affinare ulteriormente la finitura superficiale, raggiungendo un livello di levigatezza che è fondamentale per le applicazioni che richiedono un'elevata precisione, come nei circuiti integrati e nei componenti ottici.

La combinazione di questi metodi non solo migliora la qualità complessiva della superficie, ma aumenta anche l'efficienza della lavorazione. Sfruttando i punti di forza di ciascuna tecnica, i processi di lucidatura composita possono ridurre i tempi e i costi associati all'ottenimento di superfici di alta qualità nelle ceramiche di precisione. Questo approccio integrato è particolarmente vantaggioso per i componenti ceramici complessi che richiedono sia una sagomatura complessa che una finitura impeccabile.

In sintesi, i processi di lucidatura dei compositi sono una testimonianza delle strategie innovative impiegate nel campo della ceramica di precisione, dimostrando come la combinazione di tecniche diverse possa portare a risultati superiori sia in termini di qualità che di efficienza.

Conclusioni e tendenze future

Tendenze di sviluppo

La riduzione della lavorazione nella preparazione dei componenti ceramici di precisione è una tendenza significativa, guidata dall'integrazione di tecnologie di formatura quasi a rete che sfruttano i progressi dell'alta tecnologia. Queste tecnologie sono progettate per ottenere forme altamente precise e un'elevata accuratezza dimensionale, riducendo al minimo la necessità di lavorazioni successive.

Principali tecnologie di formatura near-net

| Tecnologia | Descrizione | Vantaggi |

|---|---|---|

| Stampaggio a iniezione | Combina metodi di iniezione di polimeri con processi di preparazione della ceramica. | Consente di produrre pezzi piccoli e complessi con densità uniforme. |

| Stampaggio a iniezione di gel | Integra lo stampaggio tradizionale della ceramica con metodi di polimerizzazione organica. | Produce pezzi grezzi in ceramica di dimensioni quasi nette e ad alta resistenza per forme complesse. |

| Stampa 3D | Utilizza la progettazione e la produzione assistita da computer per la costruzione strato per strato. | È adatta a parti in ceramica molto complesse senza bisogno di stampi. |

Queste tecnologie di formatura quasi a rete non solo migliorano la precisione dei componenti ceramici, ma snelliscono anche il processo di produzione, riducendo i costi e migliorando l'efficienza. Riducendo al minimo la necessità di lavorazioni estese, questi metodi aiutano a mitigare i problemi legati alla fragilità e alla durezza della ceramica, che sono sfide comuni nei processi di lavorazione tradizionali.

Si prevede che l'adozione di queste tecnologie avanzate continuerà a crescere, spinta dalla crescente domanda di componenti ceramici di precisione in vari settori high-tech, tra cui la produzione di circuiti integrati, la tecnologia laser e le applicazioni biomediche.

Esigenze di ricerca e sviluppo

Il progresso della ceramica di precisione è ostacolato da diverse sfide persistenti, in particolare nel campo delle strutture grandi e complesse. Queste sfide si manifestano in varie forme, tra cui bassi tassi di rendimento , processi di stampaggio complessi e costi di produzione elevati . Affrontare questi problemi richiede uno sforzo concertato in ricerca e sviluppo (R&S) per innovare e ottimizzare le metodologie attuali.

Uno degli ostacoli principali è il basso tasso di rendimento per strutture ceramiche complesse e di grandi dimensioni. Le tecniche di stampaggio tradizionali spesso faticano a mantenere l'uniformità e l'integrità strutturale, con conseguente spreco di materiale e aumento dei costi. Ciò richiede l'esplorazione di nuove tecnologie di stampaggio, come la stampa 3D che possono offrire un maggiore controllo sul processo di fabbricazione e ridurre gli scarti.

La complessità dei processi di stampaggio aggrava ulteriormente queste sfide. Lo stampaggio a iniezione della ceramica (CIM) e la formatura con gel a iniezione, pur essendo efficaci per i componenti più piccoli, incontrano problemi di scalabilità quando vengono applicati a progetti più grandi e intricati. Lo sviluppo di tecniche di stampaggio più versatili e scalabili è fondamentale per superare queste limitazioni. Ad esempio, l'integrazione di processi di lucidatura dei compositi con i metodi tradizionali potrebbe migliorare la precisione e l'efficienza della produzione su larga scala.

Inoltre, i costi elevati associati alla produzione di ceramica di precisione rappresentano un ostacolo significativo all'adozione diffusa. Questi costi sono dovuti alla necessità di attrezzature specializzate, di manodopera qualificata e di un'ampia post-lavorazione. Per ovviare a questo problema, è necessario trovare alternative economicamente vantaggiose e ottimizzare i processi. Tecnologie come rettifica ELID e lucidatura al plasma promettono di ridurre i costi mantenendo gli standard di alta qualità.

In sintesi, gli sforzi di ricerca e sviluppo in corso devono concentrarsi sul miglioramento dei tassi di rendimento, sulla semplificazione dei complessi processi di stampaggio e sulla riduzione dei costi di produzione. Sfruttando le tecnologie emergenti e integrando metodologie avanzate, il settore della ceramica di precisione può superare queste sfide e aprire la strada a più ampie applicazioni industriali.

Prodotti correlati

- Produttore personalizzato di parti in PTFE Teflon per reattori di sintesi idrotermale Politetrafluoroetilene Carta di carbonio e crescita nanometrica di panno di carbonio

- Produttore personalizzato di parti in PTFE Teflon per sedi di valvole a sfera in PTFE

- Tubo per forno in allumina ad alta temperatura (Al2O3) per la produzione di ceramiche avanzate

- Produttore personalizzato di parti in PTFE Teflon per capsule Petri e capsule di evaporazione

- Produttore personalizzato di parti in PTFE Teflon per personalizzazione di isolanti non standard

Articoli correlati

- Applicazioni del nanorivestimento PECVD oltre l'impermeabilizzazione e la prevenzione della corrosione

- Applicazione innovativa del PTFE nelle tenute meccaniche

- Politetrafluoroetilene (PTFE):Come il basso coefficiente di attrito promuove il progresso industriale

- La resistenza del PTFE alle alte temperature e alla corrosione:Perché è indispensabile nell'industria

- Dispositivi di reazione sperimentale organica comunemente utilizzati