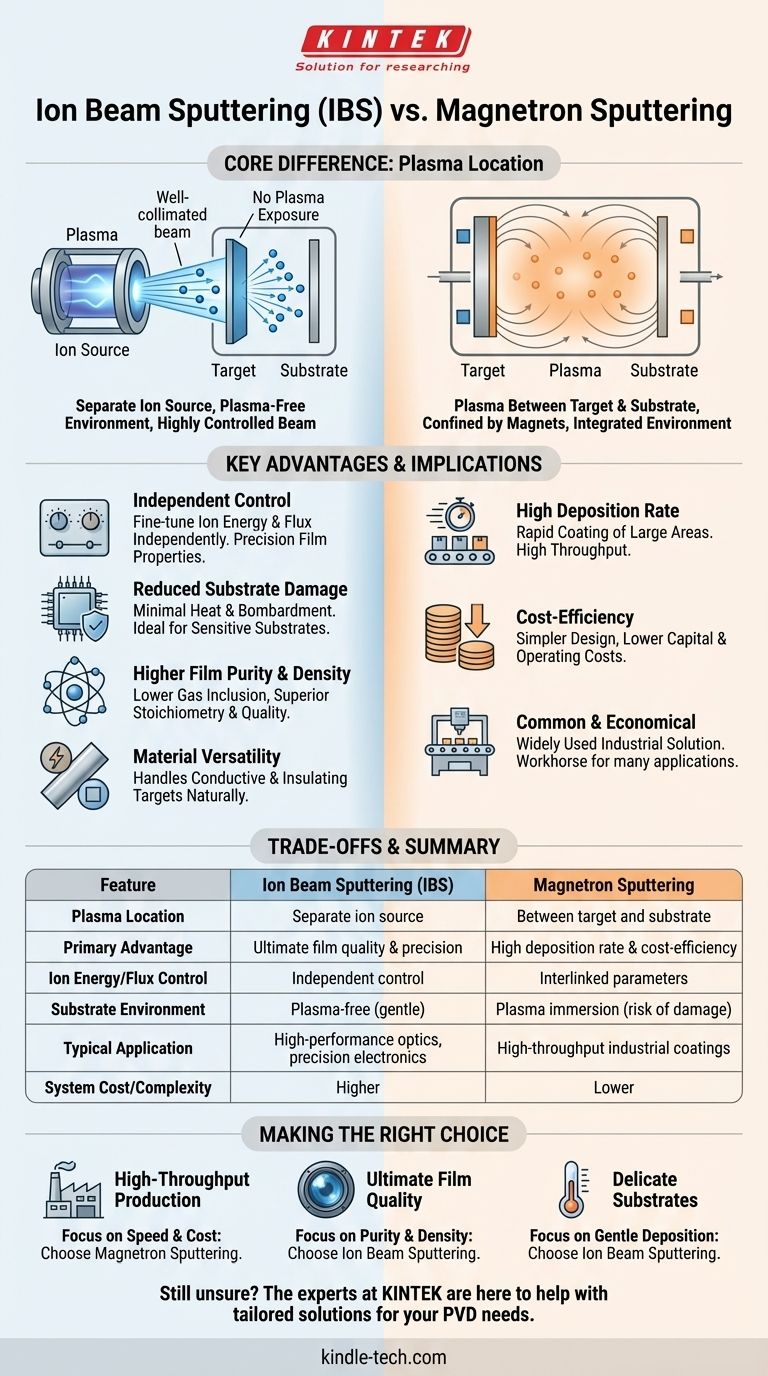

Alla base, la differenza tra lo sputtering a fascio ionico e a magnetron è la posizione del plasma utilizzato per generare gli ioni. Nello sputtering a magnetron, un plasma viene creato e confinato da un campo magnetico direttamente tra il materiale di rivestimento (bersaglio) e l'oggetto da rivestire (substrato). Nello sputtering a fascio ionico (IBS), il plasma è contenuto all'interno di una sorgente ionica separata e dedicata che genera un fascio focalizzato di ioni, che viene poi diretto verso il bersaglio in un ambiente privo di plasma.

La distinzione fondamentale è una questione di controllo. Separando la generazione di ioni dal bersaglio e dal substrato, lo sputtering a fascio ionico disaccoppia i parametri chiave del processo, offrendo un livello di precisione e qualità del film difficile da ottenere con l'ambiente plasma integrato dello sputtering a magnetron.

La Differenza Architettonica Fondamentale

La divergenza primaria tra queste due tecniche di deposizione fisica da vapore (PVD) deriva da come e dove generano gli ioni energetici che dislocano materiale da un bersaglio.

Come Funziona lo Sputtering a Magnetron: Un Plasma Confinato

Nello sputtering a magnetron, la camera è riempita con un gas inerte, tipicamente Argon. Una forte tensione negativa viene applicata al materiale bersaglio.

Questa alta tensione accende il gas in un plasma—una nuvola di ioni positivi ed elettroni liberi. Un campo magnetico dietro il bersaglio intrappola gli elettroni, aumentando drasticamente la densità del plasma vicino alla superficie del bersaglio.

Questi ioni positivi vengono quindi accelerati verso il bersaglio caricato negativamente, colpendolo con forza sufficiente a staccare, o "sputterare", atomi. Questi atomi sputtered viaggiano attraverso lo spazio pieno di plasma e si depositano sul substrato, formando un film sottile.

Come Funziona lo Sputtering a Fascio Ionico: Una Sorgente Ionica Dedicata

Lo sputtering a fascio ionico (IBS) separa fisicamente il processo in due zone distinte. La sorgente ionica contiene il plasma ed è responsabile della generazione e accelerazione di un fascio di ioni uniforme e ben collimato.

Questo fascio ionico viene quindi diretto fuori dalla sorgente e attraverso uno spazio vuoto verso il bersaglio. Il bersaglio e il substrato non sono immersi nel plasma.

Quando il fascio ionico colpisce il bersaglio, sputters il materiale in modo altamente controllato. Poiché gli ioni arrivano con un'energia e un angolo specifici, il processo di sputtering è eccezionalmente prevedibile e uniforme.

Implicazioni Chiave per la Qualità del Film e il Controllo del Processo

Questa differenza architettonica ha profonde conseguenze per il processo di deposizione e la qualità risultante del film sottile.

Controllo Indipendente (Vantaggio IBS)

Nello sputtering a fascio ionico, è possibile controllare indipendentemente l'energia ionica (quanto forte gli ioni colpiscono) e il flusso ionico (quanti ioni colpiscono il bersaglio al secondo). Ciò consente una messa a punto precisa del processo di deposizione per ottenere proprietà specifiche del film.

Nello sputtering a magnetron, questi parametri sono interconnessi con la pressione operativa e la potenza del plasma, rendendo l'ottimizzazione indipendente molto più difficile.

Danno Ridotto al Substrato (Vantaggio IBS)

Poiché il substrato non è esposto a un plasma in un sistema IBS, c'è un rischio significativamente inferiore di danni da calore o bombardamento da particelle ad alta energia vaganti. Questo rende l'IBS ideale per depositare film su substrati sensibili, come ottiche delicate o elettronica sensibile alla temperatura.

Maggiore Purezza e Densità del Film (Vantaggio IBS)

Il plasma nello sputtering a magnetron può portare all'incorporazione di alcuni atomi di gas inerte nel film in crescita, il che può compromettere la sua purezza e le sue proprietà.

L'IBS opera in un ambiente di vuoto più elevato senza plasma vicino al substrato, con conseguente minore inclusione di gas. L'energia controllata degli ioni in arrivo aiuta anche a creare film più densi, più stabili e di qualità superiore con una stechiometria superiore.

Versatilità dei Materiali

Entrambe le tecniche sono versatili. Tuttavia, per lo sputtering di materiali isolanti (non conduttivi), lo sputtering a magnetron richiede tipicamente un'alimentazione RF (Radio Frequenza) per prevenire l'accumulo di carica sul bersaglio.

L'IBS gestisce naturalmente sia materiali conduttivi che isolanti senza modifiche perché il bersaglio non fa parte di un circuito elettrico ed è semplicemente un materiale da colpire con il fascio ionico.

Comprendere i Compromessi

La scelta di una tecnica di sputtering richiede un equilibrio tra le proprietà ideali del film e i requisiti pratici di produzione.

Velocità di Deposizione vs. Precisione

Lo sputtering a magnetron offre generalmente una velocità di deposizione molto più elevata, rendendolo più adatto per rivestire rapidamente grandi aree. È il cavallo di battaglia per molte applicazioni industriali dove la produttività è fondamentale.

Lo sputtering a fascio ionico è un processo più lento e più deliberato. Il suo valore risiede nella precisione e qualità del film ineguagliabili, non nella velocità.

Complessità e Costo del Sistema

I sistemi di sputtering a magnetron sono più semplici nel design, più comuni e significativamente più economici da acquistare e utilizzare.

I sistemi IBS sono più complessi a causa della sorgente ionica dedicata e dei requisiti di alto vuoto associati. Ciò si traduce in un investimento di capitale più elevato e in maggiori costi di manutenzione.

Fare la Scelta Giusta per il Tuo Obiettivo

La tua decisione dipende in ultima analisi dai requisiti non negoziabili della tua specifica applicazione.

- Se il tuo obiettivo principale è la produzione ad alto rendimento o l'efficienza dei costi: Lo sputtering a magnetron è quasi sempre la scelta superiore per rivestire grandi aree rapidamente ed economicamente.

- Se il tuo obiettivo principale è la massima qualità, purezza e densità del film: Lo sputtering a fascio ionico è la scelta definitiva per applicazioni esigenti come rivestimenti ottici ad alte prestazioni, elettronica di precisione e ricerca.

- Se il tuo obiettivo principale è la deposizione su substrati delicati o sensibili alla temperatura: Lo sputtering a fascio ionico offre un ambiente più delicato e controllato che minimizza il rischio di danni.

La tua scelta dipende dall'equilibrio tra la necessità di prestazioni ottimali del film e i vincoli pratici di velocità di deposizione e costo.

Tabella Riepilogativa:

| Caratteristica | Sputtering a Fascio Ionico (IBS) | Sputtering a Magnetron |

|---|---|---|

| Posizione del Plasma | Sorgente ionica separata | Tra bersaglio e substrato |

| Vantaggio Principale | Massima qualità e precisione del film | Elevata velocità di deposizione ed efficienza dei costi |

| Controllo Energia/Flusso Ioni | Controllo indipendente | Parametri interconnessi |

| Ambiente del Substrato | Senza plasma (delicato sui substrati) | Immersione nel plasma (rischio di danni) |

| Applicazione Tipica | Ottiche ad alte prestazioni, elettronica sensibile | Rivestimenti industriali ad alto rendimento |

| Costo/Complessità del Sistema | Superiore | Inferiore |

Ancora incerto su quale tecnica di sputtering sia giusta per la tua specifica applicazione? Gli esperti di KINTEK sono qui per aiutarti. Siamo specializzati nella fornitura di attrezzature e materiali di consumo da laboratorio, offrendo soluzioni su misura per le tue esigenze uniche di laboratorio. Che tu richieda la massima precisione dello sputtering a fascio ionico o le capacità ad alto rendimento dello sputtering a magnetron, possiamo guidarti verso la soluzione PVD ottimale. Contatta il nostro team tecnico oggi stesso per discutere i requisiti del tuo progetto e scoprire come KINTEK può migliorare il tuo processo di deposizione di film sottili.

Guida Visiva

Prodotti correlati

- Sistema RF PECVD Deposizione Chimica da Vapore Potenziata da Plasma a Radiofrequenza RF PECVD

- Sistema di apparecchiature per deposizione chimica da vapore CVD Forno a tubo PECVD con gassificatore a liquido Macchina PECVD

- Macchina per forni a tubo per deposizione chimica da vapore potenziata al plasma rotante inclinato PECVD

- Crogiolo in rame privo di ossigeno per rivestimento a evaporazione a fascio elettronico e barchetta di evaporazione

- Sterilizzatore Spaziale al Perossido di Idrogeno VHP H2O2

Domande frequenti

- Cos'è l'apparecchiatura PECVD (Plasma Enhanced Chemical Vapor Deposition)? Una guida alla deposizione di film sottili a bassa temperatura

- Cos'è il metodo di deposizione chimica da vapore attivata al plasma? Una soluzione a bassa temperatura per rivestimenti avanzati

- In cosa differiscono PECVD e CVD? Una guida alla scelta del processo di deposizione di film sottili più adatto

- Quali sono i vantaggi del PECVD? Ottieni una deposizione di film sottili superiore a bassa temperatura

- Qual è la differenza tra PECVD e sputtering? Scegli il metodo giusto per la deposizione di film sottili